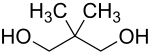

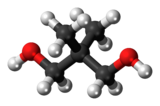

Neopentyl glycol

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

2,2-Dimethylpropane-1,3-diol | |

| Other names

2,2-Dimethyl-1,3-propanediol

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.004.347 |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| C5H12O2 | |

| Molar mass | 104.148 g/mol |

| Melting point | 129.13 °C (264.43 °F; 402.28 K) |

| Boiling point | 208 °C (406 °F; 481 K) |

| good | |

| Solubility | soluble in benzene, chloroform, very soluble in ethanol, diethyl ether |

| Thermochemistry | |

Std enthalpy of

formation (ΔfH⦵298) |

-551.2 kJ•mol−1 |

| Hazards | |

| Flash point | 129 °C (264 °F; 402 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Neopentyl glycol (IUPAC name: 2,2-dimethylpropane-1,3-diol) is an organic chemical compound. It is used in the synthesis of polyesters, paints, lubricants, and plasticizers. When used in the manufacture of polyesters, it enhances the stability of the product towards heat, light, and water. By esterification reaction with fatty or carboxylic acids, synthetic lubricating esters with reduced potential for oxidation or hydrolysis, compared to natural esters, can be produced.

Reactions

[edit]Neopentyl glycol is synthesized industrially by the aldol reaction of formaldehyde and isobutyraldehyde. This creates the intermediate hydroxypivaldehyde, which can be converted to neopentyl glycol by either a Cannizzaro reaction with excess formaldehyde, or by hydrogenation using palladium on carbon.[2]

Owing to its tendency to form cyclic derivatives (see Thorpe-Ingold Effect), it is used as a protecting group for ketones, for example in gestodene synthesis. Similarly it gives boronic acid esters, which can be useful in the cross coupling reactions.[3][4]

A condensation reaction of neopentyl glycol with 2,6-di-tert-butylphenol gives CGP-7930.

Neopentyl glycol is a precursor to Neopentyl glycol diglycidyl ether. The sequence begins with alkylation with epichlorohydrin using a Lewis acid catalyst. Dehydrochlorination of the resulting halohydrin with sodium hydroxide affords the desired ether.[5]

Research

[edit]It has been reported that plastic crystals of neopentyl glycol exhibit a colossal barocaloric effect (CBCEs), which is a cooling effect caused by pressure-induced phase transitions. The obtained entropy changes are about 389 joules per kilogram per kelvin near room temperature. This CBCE phenomenon is likely to be very useful in future solid-state refrigeration technologies.[6]

See also

[edit]References

[edit]- ^ Lide, David R. (1998), Handbook of Chemistry and Physics (87 ed.), Boca Raton, Florida: CRC Press, pp. 3‑228, 5‑42, 16‑22, ISBN 0-8493-0594-2

- ^ Weissermel, Klaus; Arpe, Hans-Jürgen; Lindley, Charlet R. (2003), Industrial Organic Chemistry (4 ed.), Wiley-VCH, pp. 214–215, ISBN 978-3-527-30578-0, retrieved 2009-07-20

- ^ p. Delaney, Connor; Heyboer, E. M.; Denmark, S. E. (2020). "Anhydrous, Homogeneous, Suzuki-Miyaura Cross-Coupling of Boronic Esters using Potassium Trimethylsilanolate". Organic Syntheses. 97: 245–261. doi:10.15227/orgsyn.097.0245. PMC 7808858. PMID 33456091.

- ^ Blair, D. J.; Zhong, S.; Hesse, M. J.; Zabaleta, N.; Myers, E. L.; Aggarwal, V. K. (2016). "Full chirality transfer in the synthesis of hindered tertiary boronic esters under in situ lithiation–borylation conditions". Chemical Communications. 52 (30): 5289–5292. doi:10.1039/C6CC00536E. hdl:1983/879ca6cc-b403-48ea-8a81-3ff6988db405. ISSN 1359-7345. PMID 27002235.

- ^ Crivello, James V. (2006). "Design and synthesis of multifunctional glycidyl ethers that undergo frontal polymerization". Journal of Polymer Science Part A: Polymer Chemistry. 44 (21): 6435–6448. Bibcode:2006JPoSA..44.6435C. doi:10.1002/pola.21761. ISSN 0887-624X.

- ^ Li, Bing; et al. (27 March 2019), Nature, pp. 506–510