Gas spring

This article needs additional citations for verification. (September 2018) |

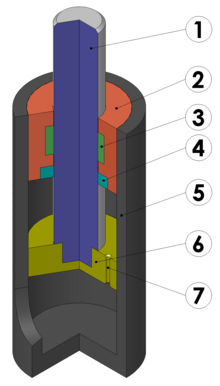

2. Head cap

3. Guide bushing

4. Seal

5. Cylinder

6. Piston

7. Flow-restriction orifice

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on elastic deformation, uses compressed gas contained within an enclosed cylinder.[1] Variable-force types rely on a sliding piston to pneumatically store potential energy and withstand external force applied parallel to the direction of the piston shaft (loosely analogous similarly to a bicycle pump without a gas outlet), while constant-force types rely on a constant pre-charged gas pressure and a difference in areas between the top and bottom of the piston to produce a constant force along the entire travel length of the shaft.[citation needed]

Gas springs are used in automobiles to support hatches, hoods, and covers.[2] They are also used in furniture and doors, as well as in medical beds.[2] They are used industrially in machine tool presses.[2] Fast-acting gas springs are used in aerospace design and weapons applications, and large, extended gas springs are used in passive heave compensators, which stabilize drilling operations against waves.[2]

Gas springs are usually implemented in one of two ways. A pneumatic suspension gas spring directly compresses a chamber of air with the piston. A hydro-pneumatic suspension gas spring instead compresses a chamber of oil linked to an accumulator in which the pressure of the oil compresses the gas.[3] Nitrogen is a common gas in gas springs because it is inert and nonflammable.[2]

Forms

[edit]Pneumatic gas springs typically come in two forms: variable-force and constant-force.[citation needed]

Variable-force

[edit]In a variable-force gas spring, the gas in the cylinder is compressed as force is applied, causing it to push back against the piston surface in proportion to the amount of force being applied. The resulting effect is similar to that of a conventional elastic spring, since the force needed to further compress the spring increases linearly as the spring is compressed, as described by Hooke's law.[citation needed]

Constant-force

[edit]In a constant-force[citation needed] gas spring, the cylinder is filled with a charge of high-pressure[4] gas to begin with, and the piston contains a number of orifices that allow the gas to transfer between the lower chamber (between the piston and the closed end of the cylinder) and the upper chamber (between the piston and the head cap).[1] This causes the pressure in both chambers to equilibriate no matter how far the piston is pushed down the tube.[1]

By the kinetic theory of gases, for a gas at a constant pressure in a closed container, the amount of outward force exerted by the gas on the inner container walls is proportional to their surface area. Because the top surface of the piston has a smaller effective area than its bottom surface (due to the piston rod being attached to the top), the gas always exerts a greater force in the direction of travel on the bottom of the piston than on the top, resulting in a net force pushing the piston rod out of the cylinder.[citation needed] Since the pre-charged gas pressure remains the same in both chambers, the force remains constant along the entire length of the cylinder, resulting in a spring which, uniquely, applies the same linear force no matter how much it gets compressed.[dubious – discuss][citation needed]

The size and geometry of the piston orifices can also be tuned in a way that restricts or impedes the flow of gas between the two chambers, causing the pressure in the two chambers to equilibriate more slowly. This allows for some pressure accumulation in either chamber as the spring is compressed or extended quickly, giving such gas springs a mild shock-absorbing effect similar to that of a viscous damper.[citation needed]

Gas springs whose pistons have fine holes in them for damping are called slow-damper springs and are common on safety gates and doors.[2]

Other details

[edit]If the internal plunger features a diaphragm that extends to the side of the gas tube, it will stop moving once the applied force becomes constant and will support a weight, like a normal spring.[citation needed] Some gas springs have fine holes in the plunger for additional damping:[how?] these are called "slow-damper springs" and are common on safety gates and doors.[2] A gas spring designed for fast operation(s) is termed a "quick gas spring" and is used in the manufacture of air guns and recoil buffers.[citation needed]

It is possible to reduce the gas volume and increase its internal pressure by means of a movable end stop, or by allowing one tube to slide over another, allowing the characteristics of a gas spring to be adjusted during operation. The rod may be hollow by use of clever seals, or it may consist of multiple small-diameter rods. A small amount of oil is normally present.

The gas may be introduced by a Schrader-type valve, using a lip seal around the rod and forcing it to allow gas in by external overpressure or a shuttling O-ring system. Gas springs with high caliber contain a very large amount of energy, and can be used as a power pack. In emergency use, the gas may be introduced via a gas generator cell, similar to those used in airbags.

Variations

[edit]A gas spring can be given adjustable push-in force via a local knob or remote via a Bowden wire.[citation needed]

Extended stroke is usually acquired through telescoping mechanisms, composed of one rod and multiple cylinders, where the smaller of the two cylinders actually acts as a second rod extending in and out of the larger cylinder.[2]

There are also techniques to make variable-lift gas springs. These are intended for short production runs and prototypes, and in applications where the exact force is important but hard to estimate in advance, such as lifting a lid slowly in a known time. In this case, the cylinder is supplied filled to maximum design pressure but equipped with a bleed port to allow gas to be released once installed. The intention is that the design can be over-sprung, and then the pressure is reduced in stages to optimize behavior. If too much gas is released, a new spring must be installed.[citation needed]

It's also possible to make degressive gas springs, where the spring becomes more, not less, powerful as the main cylinder expands.[5]

See also

[edit]References

[edit]- ^ a b c "Understanding the Basics of Gas Spring Application". Tech Briefs. 2019-04-01. Retrieved 2024-03-31.

- ^ a b c d e f g h Eitel, Lisa (7 August 2017). "What are gas springs? A technical primer". Motion Control Tips. Retrieved 2024-07-22.

- ^ Savaresi, Sergio M.; Poussot-Vassal, Charles; Spelta, Cristiano; Sename, Olivier; Dugard, Luc (2010-08-13). "Semi-Active Suspension Technologies and Models". Semi-Active Suspension Control Design for Vehicles. Elsevier. ISBN 978-0-08-096679-3.

- ^ "Pneumatic Handbook". ScienceDirect. Retrieved 2024-09-12.

- ^ "Degressive gas spring".